Categories

Archives

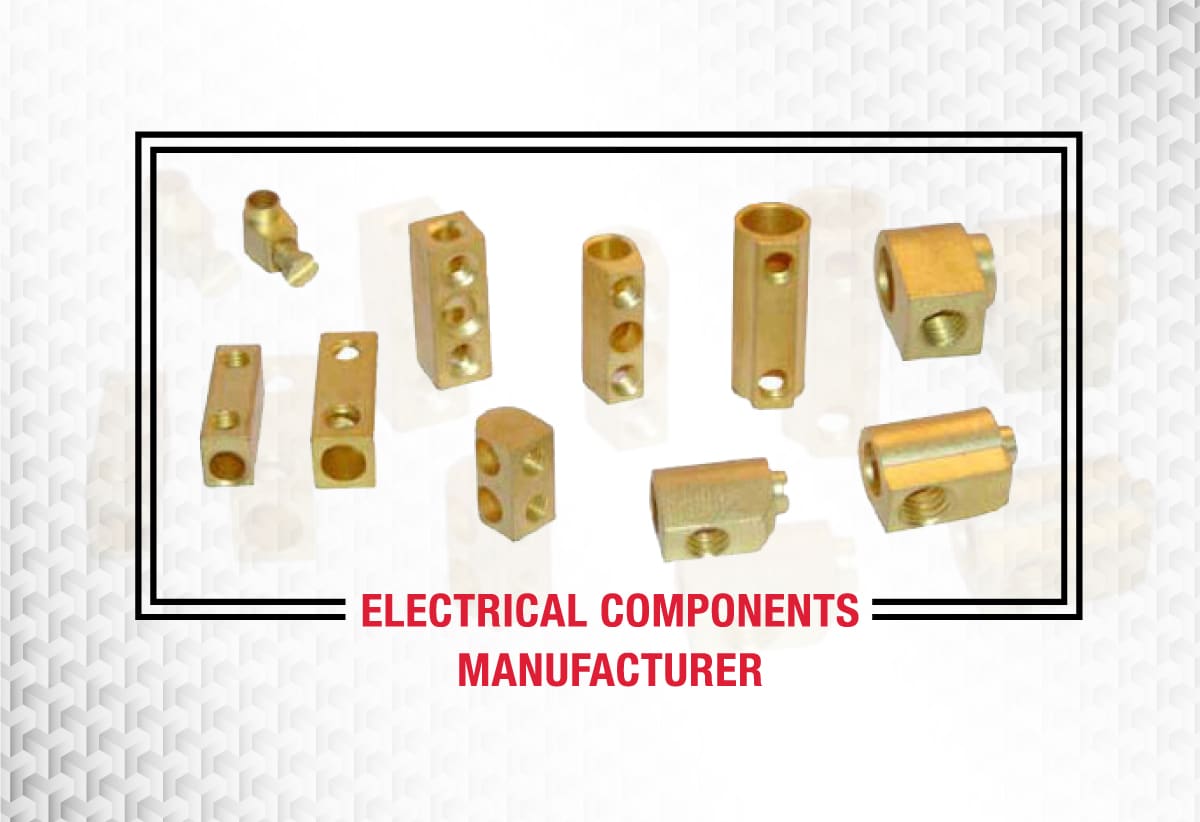

Factors to Consider When Selecting Brass Material for Electrical Components

Brass is an alloy composed of copper and zinc and is known for its corrosion resistance, hardness, thermal conductivity, strength, and workability. It is a non-magnetic alloy with low friction and a variety of colours ranging from deep red to golden yellow. By adjusting the copper and zinc content, different mechanical and electrical properties can be achieved. It is possible to produce various kinds of brass by altering the copper-zinc ratio. Brass is used in a wide range of industries because of its different grades.

Choosing brass for electric components might be a bit difficult. Since there are various grades of brass, you need to consider which of these brass grades’ characteristics are a fit for your electric components. In this blog post, we’ll take a closer look at the various brass grades and factors to choose the right one that is commonly used for electric components.

Types of Brass Grades for Electrical Components

Brass is classified into different grades based on the amount of copper and zinc it contains. Different grades of brass also have different properties due to their variation in composition. We will review some of them here along with their advantages, disadvantages, and applications. Following are some factors that you might want to consider:

1. Brass C360

This alloy is commonly referred to as free-machining brass by manufacturer of electrical components. It is the most common brass grade used in machining. It is known for its high machinability and tensile strength. Due to its high lead content, which makes up about 3% of its composition, it is highly machinable.

Advantages

- Easily machinable.

- Corrosion resistance.

- Good tensile strength.

Disadvantages

- If lead content is used in medical applications, it could cause issues.

- Susceptible to acids.

2. Brass C230

Many metal component manufacturers refer to this brass grade as red or Nordic brass. Brass C230 has moderate strength but is significantly stronger than yellow brass and has highly effective anti-rust properties. It is the most preferred brass type because of its ability to resist dezincification and seasoning. Manufacturers also use it for making pipe service lines due to its resistance to water corrosion. It is ideal for custom brass components, parts, or products.

Advantages

- Resistance to dezincification.

- Moderate tensile strength.

- Easily cold worked, hot formed, soldered, and brazed.

- Most durable for commercial and industrial.

Disadvantages

- In harsh environments, it might not be able to withstand corrosion.

3. Brass C220

Manufacturers of industrial electrical components refer to this alloy as commercial bronze. The higher copper content still makes it a brass alloy despite its name. It has a high machinability rating, strength, and flexibility. It is a favourite in the architectural world and is used to manufacture weather stripping.

Advantages

- Excellent corrosion resistance.

- Good machinability rating.

- High capacity for being cold worked.

Disadvantages

- The material might need to be annealed more after exposure to harsh conditions.

4. Brass C300

Brass grades C300 to C30000, which are also known as intermediate brasses or alpha-beta brasses, have a balance of copper and zinc. Their attributes make them suitable for a variety of applications across various industries, providing them with a comprehensive set of attributes.

Advantages

- Balance between strength and ductility.

- Easily shaped and formed.

- Exhibit good corrosion resistance.

- Offer good machinability.

Disadvantages

- Expensive compared to other grades.

- Regular maintenance requires.

Machining Time of Electrical Components

It is important to consider the lead times for different projects when determining which brass grade to use. For electrical components, the C360 is the most suitable brass grade in terms of machinability. So, if you need custom brass electrical components urgently, the C360 is an overwhelming material favourite. However, if you require other properties apart from machinability, you could assess other grades like the C230 or the C220.

Electrical Component Design

You should ensure your parts design is not too complex for machining, even though brass grades are quite easy to machine. Furthermore, it is recommended to minimize the number of machine setups. In this way, the machining cost of the project can be reduced.

Application of Electrical Components

There are various strengths and weaknesses to each brass grade because of their different compositions. Depending on how you plan to use the component, the brass will be suitable for electrical components. If you decide that brass is the right metal for your electrical component, you should make sure that its applications match the brass grade’s property profile.

Brass is an incredibly versatile material that can be used in a wide variety of applications due to its durability, malleability, strength, and corrosion resistance properties. There are several types of brass alloy compositions available on the market today, each offering unique characteristics suited for specific tasks depending on the desired outcome. Whether you’re looking for a material with superior machinability or one with excellent wear resistance – there is sure to be a brass alloy out there that meets your needs! For engineers and materials scientists who work with brass alloys regularly – understanding these different compositions can help inform their decisions when selecting the best option for your electrical component requirements.

Considering all the factors discussed above will help you make the right decision to choose brass grade for high-quality electrical components. And still, if you are not sure, or just want to talk through your requirements. Our team of experts can simplify the manufacturing process for you, helping to select the right brass grade for electrical components. To learn more about our services and offered range of brass components, contact us at info@brasscomponent.co.uk or request a quick quote!

Top 10 Custom Brass Components Manufacturers in UK 2023

Brass Components are a broad range of mechanical parts or components that can be used to connect and disconnect objects in a permanent or semi-permanent manner. Brass Components are widely used in every type of industry, and residential application such as automotive, machinery, furniture, infrastructure, appliances, electrical, electronics, telecommunication, aerospace, construction, agricultural, energy, repair & maintenance, military, and many more.

There are several types of brass components including brass electrical components, brass handrail components, brass lighting components, brass turned components, brass forging components, brass jewellery components, brass lamp components, brass machined components, brass precision components, brass railing components, brass sheet metal components, brass CNC components, soldering brass components, hydraulic brass components, pneumatic brass components, compression brass components, tubular brass components, and many more are available in the different specification for a different application.

The brass market is huge, there are many small, medium, and large size brass components manufacturers. Having said that, there are many places where you can purchase brass components in the UK but finding the right one can be challenging.

We’ve compiled a list of the top 10 UK brass components manufacturers, each offering something unique and valuable to the brass industry.

List of the top 10 UK brass components manufacturers

1. Brass Component UK

Main products: Brass Components, Split Bolt Connectors, Neutral Links, Electrical Fasteners, etc.

Email: info@brasscomponent.co.uk

As a leading brass components manufacturing company with 30+ years of experience, we are specialized in providing custom brass components, split bolt connectors, and neutral links based on product samples, product drawings, or specific requirements. All our offered brass components are available in various metal materials such as brass, copper, aluminium, steel, stainless steel, mild steel, bronze, and brass alloys with utmost precision. Whether you need a medium, large or very large quantity, we will match your needs. No matter what your requirement is, we have the right brass components or parts for you.

2. Woodstock Parts UK Ltd

Location: Unit 1A, Winchester Avenue, Blaby Industrial Park Blaby, Leicester LE8 4GZ, England, UK.

Main products: Turned & Machined Parts, Special Fasteners, etc.

Email: sales@patternfasteners.co.uk

Since establishment in 1981, Pattern Fasteners are one of the leading fastener companies in the West Midlands; a specialist in the field of non-standard fasteners and precision components. They have a valuable experience in the engineering industry and passionate team of staff have developed strong knowledge and expertise in this area. They manufacture fasteners, bolts, screws, washers, and other precision brass components with precision and a level of dimensional accuracy. All the fasteners are constructed from the best quality materials and cutting-edge machinery. From nuts and bolts to washers and pins, they have everything for every industry and all fasteners can be tailored to meet customer’s individual needs and requirements.

3. PATTERN FASTENERS LTD.

Location: Unit 31, Hainge Road, Oldbury, West Midlands, B69 2NY, UK.

Main products: Turned & Machined Parts, Special Fasteners, etc.

Email: sales@patternfasteners.co.uk

Since establishment in 1981, Pattern Fasteners are one of the leading fastener companies in the West Midlands; a specialist in the field of non-standard fasteners and precision components. They have a valuable experience in the engineering industry and passionate team of staff have developed strong knowledge and expertise in this area. They manufacture fasteners, bolts, screws, washers, and other precision brass components with precision and a level of dimensional accuracy. All the fasteners are constructed from the best quality materials and cutting-edge machinery. From nuts and bolts to washers and pins, they have everything for every industry and all fasteners can be tailored to meet customer’s individual needs and requirements.

4. Flowflex Components LTD

Location: Samuel Blaser Works, Buxton, SK17 7LR, UK.

Main products: Capillary fittings, Compression Fittings, Press fittings, Valves, etc.

Email: hello@flowflex.com

Founded in 1954, Flowflex is a family-owned business who are leading in the manufacturing and suppling of high-quality non-ferrous plumbing fittings. They design products for use in all applications of plumbing and heating trade and are recognized for their quality and reliability. Their comprehensive product portfolio includes a wide range of compression, copper, and copper alloy plumbing fittings. In addition, they offer valves in a variety of configurations and sizes. With in-house design and testing capabilities, they can turn your designs into prototypes quickly with tight deadlines. Flowflex is committed to providing high-quality products and exceptional customer services to its valued clients from various industrial segments.

5. M&M Turned Parts Ltd

Location: Unit 3 Securehold Business Centre, Studley Road, Redditch, Worcestershire B98 7LG, UK.

Main products: CNC Turned components, Brass Turned Parts, Steel Turned Parts, etc.

Email: sales@mmturnedparts.co.uk

Established in 1990 by Edward Moss, M&M Turned Parts Ltd is a subcontract machining company based in Redditch, Worcestershire. They provide CNC Sliding Head turning in addition to CNC Fixed Head turning services from their facility located near Birmingham, West Midlands. Competitively priced, quality components are manufactured for a customer base spanning the UK and Europe. They manufacture CNC turned components, steel turned parts, stainless steel turned components, plastic turned components, brass turned parts, aluminium turned parts, and more. Above all, M&M Turned Parts Ltd is capable of machining parts from 2mm to 65mm in batch sizes of 200 components to 100,000 upwards. They prioritize quality with UKAS ISO 9001-2015 accredited quality system. Their flexibility allows for the manufacturing of CNC machined components for many sectors such as fastener, hydraulic, pneumatic, and more.

6. Currie & Warner

Location: Summer Hill Works Powell Street, Birmingham, West Midlands, B1 3DH, England.

Main products: Brass Fasteners, Brass Connectors, Brass Fittings, Valves, Adaptors, etc.

Email: sales@curriewarner.com

Since 1855, Currie & Warner Ltd. has a vast amount of experience in manufacturing brass-turned parts and machined components supplying in a wide variety of sectors from Electrical, Sanitary, Automotive, Pneumatics, Telecommunication Heating Controls, and Gas Related industries globally. The most common specification machined by them is equivalent to American specifications and materials such as lead-free brass, free cutting brass, DZR (De-Zincification Brass), Nickel Brass, Gun Metal (Red Brass), CDA360, CZ122, CZ124, CZ128, CZ129, CZ131, AISI 12L14, and other brass specifications. Turned parts or screw machined parts are manufactured on multi-spindle conventional machines to ensure cost-effectiveness, with a size range capacity from 10mm to 57mm Diameter.

7. Technifast Ltd

Location: North Folds Road, Oakley Hay Industrial Estate, CORBY, Northamptonshire, NN18 9AT, UK.

Main products: Dowels pins, Grooved pins, Taper pins, spacers, inserts, engineer’s keys, and other products, etc.

Email: sales@technifast.co.uk

Technifast Ltd is an ISO:9001 registered supplier, distributor and manufacturer of specialist precision engineering components and fasteners. The core product range comprises pins, dowels, spacers, inserts and engineers’ keys, the majority of which are available for same day despatch from their warehousing facility. They can quote as per customer specifications within their manufacturing facilities in Corby. Technifast Ltd has over thirty years of experience in providing precision fasteners and bespoke turned parts to a multitude of industries at an international level. Technifast Ltd’s manufacturing division is dedicated in producing small and complex turned parts, using CNC machines to obtain high precision and an excellent surface finish. They are producing both high-volume runs of parts and low-volume orders such as prototype manufacturing.

8. Efficient Fasteners

Location: Unit 48 Sapcote Trading Centre, Powke Lane Cradley Heath West Midlands, B64 5QX, UK.

Main products: Precision turned parts, Brass turned parts, Plastic turned parts, Fixings, Fasteners, etc.

Email: burnsbros@hotmail.com

Efficient Fasteners is a long-established company with a reputation for supplying turned parts. They offer precision turned parts, assembly, fixings and fasteners with a rapid turnaround, offering a cost-effective solution. Their in-house facility offers rapid prototype work and small urgent batch quantities, giving flexibility and scope to customers, from design to prototyping, before going into production through a global supply network. From established in 1990, they supply and manufacture a wide range of affordable, high-quality precision-turned parts, fixings, and fasteners across several different sectors. Efficient Fasteners built a reputation in the industry as a reliable and experienced precision-turned parts manufacturer working closely with customers, building a customer-supplier relationship that is tailored to your specific requirements to advise the very best solution for you.

9. Sub-CNC Precision Ltd.

Location: Unit O, Cradock Road Industrial Estate, Luton, Bedfordshire LU4 0JF, UK

Main products: Machined Components, Turned Parts, Milled components, etc.

Email: info@berkshirebrass.co.uk

Founded in 2008, Sub-CNC Precision Ltd is an engineering company specializing in producing high-quality machined components for a diverse range of industry sectors, including Aerospace, Defence, Medical, Oil & Gas, Electronics, and Motorsport. They offer high-quality components for over a decade to multiple industry sectors of UK and across Europe, and over recent years have begun to export globally. With the backing of the ISO 9001 registered system, you can be sure of their consistency and performance. They provide a friendly, reliable service and support you in meeting the demands of clients and markets. They can manufacture any batch size from prototype to high volume turned parts with sliding head bar capacity up to 35mm and fixed head bar capacity up to 65mm diameter.

10. Berkshire Brass Products.

Location: 60, Cartmel Drive Reading RG5 3NQ, UK.

Main products: Brass Anchor, Brass Electrical Parts, Brass Fasteners, Brass Moulding Insert, Decorative Parts, Split Bolt and Line Tap, Socket & Pins, Cable Gland, Sanitary Pants, etc.

Email: info@sub-cncprecision.co.uk | sales@berkshirebrass.co.uk

Berkshire Brass Products is a manufacturing and exporting company specializing in a variety of Brass Products and Components as per the requirements of the clients. They also supply ferrous and non-ferrous metal components. They have an experienced team in the brass products manufacturing business and supply a range of products in the UK, United States, and Europe. The company’s extensive programs continue to improve quality standards throughout all manufacturing phases, starting with the raw materials and ending with incoming materials. The company offers a wide range of surface finishing, heat treating, coating, and plating services through its network of highly qualified vendors.

As a well-established brass components manufacturing, exporting, and supplying the company with more than three decades of years of experience, we have been offering quality and precise solutions for all sizes of projects across the UK, USA, and Europe. If you are looking for high-quality brass components for your projects, we have the expertise in custom, OEM, and contract brass components manufacturing services at your request, at a competitive price. Request a free quote, we will be happy to discuss your project and requirements.